Home > Solution > Solution

Lead-zinc mine production

Lead Zinc Ore Product Introduction

Lead and zinc ore is a mineral rich in metal elements, lead and zinc. Its hardness is 3-3.5 in Mohs. There are 11 kinds of lead minerals that can be used in industry. There are 6 kinds of zinc ore, and the most important is the galena, sphalerite, the bonamite and white lead ore. Lead and zinc is widely used in the fields of electrical industry, mechanical industry, military industry, metallurgical industry, chemical industry, light industry and pharmaceuticals. In addition, lead metals in the nuclear industry, oil industry and other departments also have more uses.

Technical Process

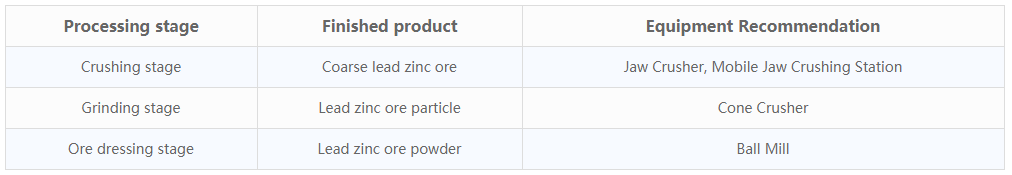

The processing technology of lead zinc ore mainly includes three processes: crushing, grinding and ore dressing. In the process of crushing, three sections of closed circuit crushing are the most scientific ones suitable for high hardness lead-zinc ore, which can complete the crushing and partial dissociation of ore, thus improving the efficiency of subsequent grinding. During the grinding process, the two parts of a closed grinding mill are efficient grinding process, which can make lead and zinc ore more fully ground. Ore dressing process uses the integrated rapid flotation technology and can make the original complex flotation system improved for two sets of integrated rapid flotation system to complete, which greatly shortens the process and is beneficial to ensure the quality of the concentrate and reduce the investment.

Massive lead zinc ore is sent into jaw crusher or mobile jaw crusher station uniformly by vibrating feeder through stock bin for coarse crushing. After crushing, the lead zinc ore is screened by vibrating screen. The qualified lead zinc ore is sent to single cylinder hydraulic cone crusher by belt conveyor for secondary crushing. And the unqualified ore is transported to jaw crusher to continue to crush once again by belt conveyor. After secondary crushing, the lead zinc ore is sent into multi-cylinder hydraulic cone crusher for fine crushing. The lead zinc powder of 0-12mm screened by vibrating screen is transported to ball mill uniformly for grinding and is sorted by spiral classifier. The unqualified lead zinc powder is sent to ball mill to go on grinding. The lead zinc powder which meets the requirement is sent into the flotation machine to carry out mixed flotation, and then the powder will be sent into the dryer and the lead zinc powder can be obtained.

Equipment Recommendation

Contact Us:

Phone: 0086-371-66888887

Mobile: 86-18203639337

WeChat: 18203639337

Email: sales@bljq.com

Online store: https://zzbailing.en.alibaba.com