Home > Products > Rotary Kiln > Products

Introduction

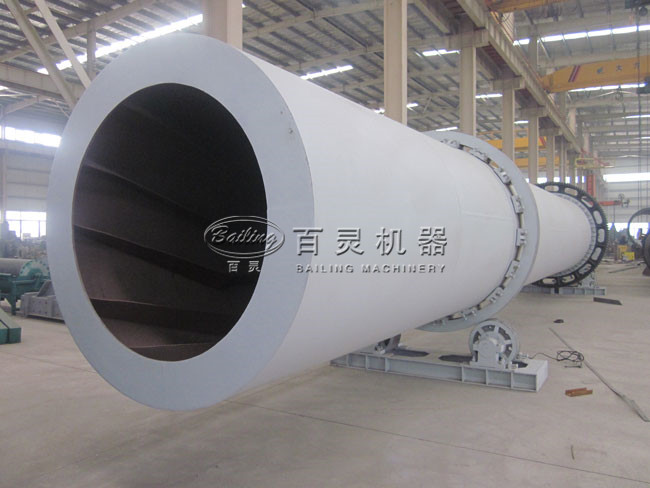

Product description:

Soil ceramic kiln is widely applications, mainly applicable to ceramic sand, yellow mud, fly ash., etc. Ceramic kiln operating temperature can generally reach 950-1050 degrees Celsius.

Features:

1. soil ceramic kiln produced by Bailing machinery with high specialization degree,

2. can achieve temperature automation control , especially the over-temperature alarm system installed improved the quality of calcined material security

3. the new type ceramic rotary kiln can take advantage of the secondary preheating air, improved equipment energy saving effect.

4. kiln head and kiln end using advanced sealing technology and device, stable equipment operation and, greatly extended the using life.

Soil ceramic kiln is widely applications, mainly applicable to ceramic sand, yellow mud, fly ash., etc. Ceramic kiln operating temperature can generally reach 950-1050 degrees Celsius.

Features:

1. soil ceramic kiln produced by Bailing machinery with high specialization degree,

2. can achieve temperature automation control , especially the over-temperature alarm system installed improved the quality of calcined material security

3. the new type ceramic rotary kiln can take advantage of the secondary preheating air, improved equipment energy saving effect.

4. kiln head and kiln end using advanced sealing technology and device, stable equipment operation and, greatly extended the using life.

Parameter

|

Specification (mm) |

Kiln body size |

Capacity (t/h) |

Rotation speed (r/min) |

Motor power (kw) |

Weight (t) |

Remark | ||

|

Diameter (mm) |

Length (mm) |

Slope (%) |

||||||

| φ1.4×33 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 | ---- |

| φ1.6×36 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 | ---- |

| φ1.8×45 | 1.8 | 45 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 | ---- |

| φ1.9×39 | 1.9 | 39 | 4 | 1.65-3 | 0.29-2.93 | 30 | 77.59 | ---- |

| φ2.0×40 | 2 | 40 | 3 | 2.5-4 | 0.23-2.26 | 37 | 119.1 | ---- |

| φ2.2×45 | 2.2 | 45 | 3.5 | 3.4-5.4 | 0.21-2.44 | 45 | 128.3 | ---- |

| φ2.5×40 | 2.5 | 40 | 3.5 | 9.0-10.5 | 0.44-2.44 | 55 | 149.61 | ---- |

| φ2.5×50 | 2.5 | 50 | 3 | 6.25-7.4 | 0.62-1.86 | 55 | 187.37 | ---- |

| φ2.5×54 | 2.5 | 54 | 3.5 | 6.9-8.5 | 0.48-1.45 | 55 | 196.29 | ---- |

| φ2.7×42 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 | ---- |

| φ2.8×44 | 2.8 | 44 | 3.5 | 12.5-13.5 | 0.437-2.18 | 55 | 201.58 |

suspension preheater kiln |

| φ3.0×45 | 3 | 45 | 3.5 | 12.8-14.5 | 0.5-2.47 | 75 | 210.94 | ---- |

| φ3.0×48 | 3 | 48 | 3.5 | 25.6-29.3 | 0.6-3.48 | 100 | 237 | outside decomposition kiln |

| φ3.0×60 | 3 | 60 | 3.5 | 12.3-14.1 | 0.3-2 | 100 | 310 | ---- |

| φ3.2×50 | 3.2 | 50 | 4 | 40.5-42 | 0.6-3 | 125 | 278 | outside decomposition kiln |

Contact Us

- Electrical Industry Zone Of Zhengzhou, Henan, China (Mainland)

- 0086-371-67996061

- blmachinery@bljq.net

- www.bailingmachinery.com/

If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, a representative will contact you within one business day. We guarantee that your information will not be divulged to the third party.